Foshan Large Capacity High Quality PVD Coating Machine for Glassware & Stainless Steel

Advanced PVD metallizing machine for stainless steel gold coating and other decorative finishes. This high-quality PVD ion vacuum coating equipment delivers superior durability and aesthetic results for various industrial applications.

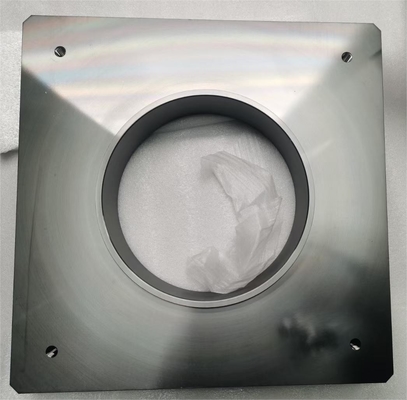

A PVD (Physical Vapor Deposition) coating machine is a specialized device used to apply thin film coatings onto various substrates. This advanced technology involves vaporizing solid materials in a vacuum chamber and depositing them onto surfaces to enhance durability, corrosion resistance, and aesthetic appeal. PVD coating machines are widely used in industries such as automotive, aerospace, medical devices, and consumer electronics.

The process begins by placing the substrate in a vacuum chamber, where the target material is vaporized through methods like sputtering or evaporation. The vaporized particles then condense on the substrate, forming a uniform, high-performance coating. PVD coatings are known for their hardness, wear resistance, and ability to maintain precision dimensions.

These machines offer advantages such as environmental friendliness, as they produce minimal waste compared to traditional coating methods. They also enable the deposition of various materials, including metals, ceramics, and alloys, providing versatility for different applications. With precise control over coating thickness and composition, PVD coating machines ensure consistent quality and performance, making them essential in modern manufacturing.

Q: How about your company?

A: We are a leading manufacturer and provider of total integrated supply chain solutions for vacuum coating machines.

Q: How about the quality control about our products?

A: We have the ISO9001 QMS-Quality Management System.

Q: Do you provide after-sales service?

A: After-sales problems shall be solved online within 48 hours. Long-term product solution and remote technical support is provided.

Q: What about the payment terms?

A: T/T and it is also flexible according to different types of machine.

Q: About the package?

A: Nude packing or wooden case carton container.

Q: Do you provide the second-hand machine?

A: Yes. We also provide second-hand machines - you can provide your requirements to our salesman.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!